联系我们

济南聚大邦成化工有限公司

联系人:张总

电话:13583111587

网址:www.jnjdbc.cn

地址:济南市天桥区新材料市场南区7-1-1

无水葡萄糖在生产时的干燥方式有哪些?

来源:http://www.jnjdbc.cn/ 日期:2021-09-07 发布人:admin

无水葡萄糖是输液或中医针灸消费的替代品,是美国和日本对注射用葡萄糖的要求,也体现在国家药典中。例如,日本处方规定,无水糖是葡萄糖注射的原料。与一水葡萄糖相比,它具有无热源反应,杂质含量低,纯度高等优点。现在,我们来看看无水葡萄糖在生产中的干燥方法。

Anhydrous glucose is a substitute for infusion or TCM acupuncture consumption. It is the requirement of the United States and Japan for glucose for injection, which is also reflected in the national pharmacopoeia. For example, the Japanese prescription stipulates that anhydrous sugar is the raw material for glucose injection. Compared with glucose monohydrate, it has the advantages of no heat source reaction, low impurity content and high purity. Now, let's look at the drying method of anhydrous glucose in production.

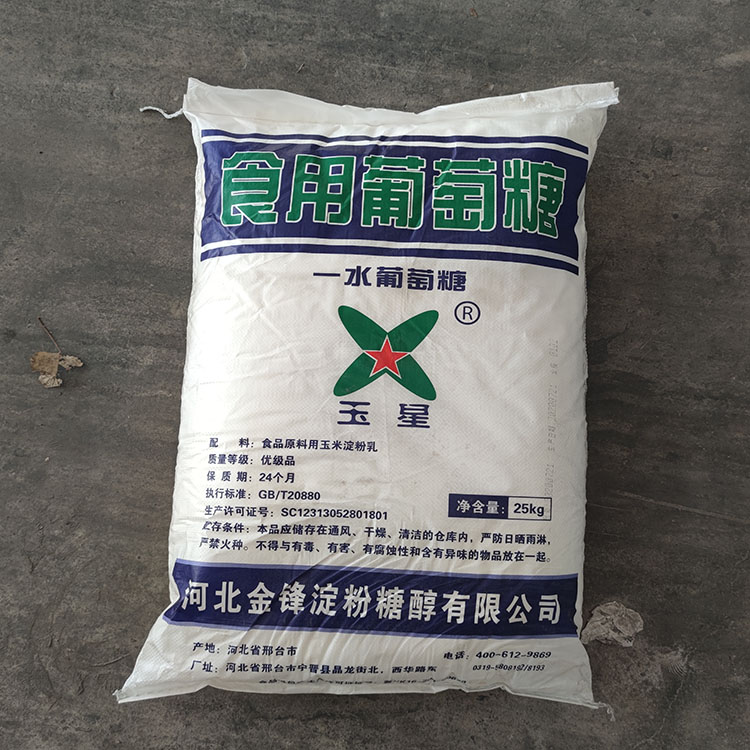

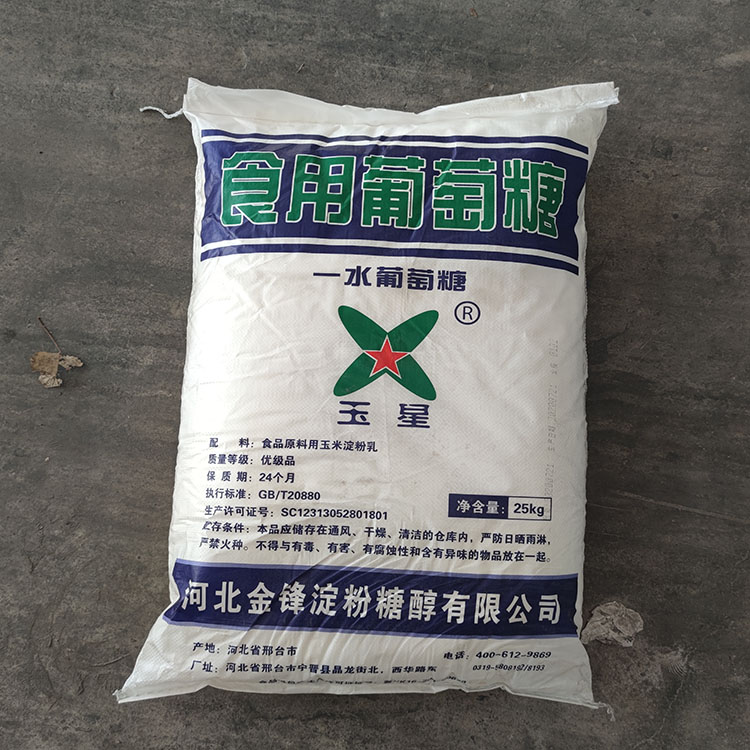

制药工业中,无水葡萄糖生产的葡萄糖注射液、葡萄糖氯化钠注射液,在进食减少或由于某些原因不能进食时,可用于补充热能;对低氧血症、饥饿酮症、失水等有良好的医疗效果。本品消耗多采用双酶法,以淀粉乳为原料,经液化、糖化、去渣、脱色、分离、蒸发、结晶、分离等精制处理,得到一水葡萄糖,再经溶糖、脱色、煮糖、分离、制孔、包装等工序制成。

In the pharmaceutical industry, glucose injection and glucose sodium chloride injection produced by anhydrous glucose can be used to supplement heat energy when eating is reduced or unable to eat for some reasons; It has a good medical effect on hypoxemia, hunger ketosis and water loss. This product is mostly consumed by double enzyme method. With starch milk as raw material, glucose monohydrate is obtained through refining treatment such as liquefaction, saccharification, slag removal, decolorization, separation, evaporation, crystallization and separation, and then made through sugar dissolution, decolorization, sugar boiling, separation, pore making, packaging and other processes.

因为无水葡萄糖不含晶体水,杂质和微生物的引入大大降低。产品干燥是消费行业的关键一步。煮沸结晶分离后,物料含水量一般在2%左右,干燥设备的效率直接影响到整个消耗效率和产量。干燥器的性能是保证产量和质量、节能的关键环节。

Because anhydrous glucose does not contain crystal water, the introduction of impurities and microorganisms is greatly reduced. Product drying is a key step in the consumer industry. After boiling crystallization separation, the water content of the material is generally about 2%, and the efficiency of the drying equipment directly affects the whole consumption efficiency and output. The performance of dryer is the key link to ensure output, quality and energy saving.

目前,流化床是无水葡萄糖消费企业产品的主要干燥设备。流化床具有护理产量低、故障率低、维护麻烦、运行可靠等优点。然而,混合床设备运行难以控制,沸腾效果差,单位面积产量低。与去年同期相比,流化床钻孔效率低,不利于大规模消耗,产品单一消耗高。

At present, fluidized bed is the main drying equipment for anhydrous glucose consumption enterprises. Fluidized bed has the advantages of low nursing output, low failure rate, troublesome maintenance and reliable operation. However, the operation of mixed bed equipment is difficult to control, the boiling effect is poor, and the output per unit area is low. Compared with the same period last year, the drilling efficiency of fluidized bed is low, which is not conducive to large-scale consumption, and the single product consumption is high.

风扇是无水葡萄糖,消是消费干燥过程中重要的辅助设备之一,用于该干燥系统的鼓风机和鼓风机,采用马达工频恒速运转方式。然后,通过入口挡板调节风量,自动控制流化床内的压力。其缺点是无法有效控制马达,无论系统负荷是否变化,马达都处于工频运转模式。

The fan is anhydrous glucose and is one of the important auxiliary equipment in the consumption drying process. The blower and blower used in the drying system adopt the motor power frequency constant speed operation mode. Then, the air volume is adjusted through the inlet baffle to automatically control the pressure in the fluidized bed. Its disadvantage is that it can not effectively control the motor. Whether the system load changes or not, the motor is in power frequency operation mode.

下一篇:存储环境对精萘性能有什么影响? 上一篇:无水葡萄糖在养殖业中的应用!

此文关键词:

推荐阅读/ Recommended reading

- 精萘厂家:羊毛脂有什么特性 2025-04-18

- 精萘厂家:产业支柱与创新驱动者 2025-04-15

- 质量把控:企业的生命线 2025-04-14

- 精萘厂家的优势有什么 2025-04-11

为什么精萘不容易制作出来,带你从制作方法上来看看

[2018-08-23]

精萘的制备工艺Preparation process of refined naphthalene熔融 - 结晶法:这是一种较为常见且高效的制备方法。先将粗萘加热至熔融状态,利...